Since the date of its foundation in 1942, NANIWA has been supplying

patterns, core boxes and core-setting jigs to the foundry industry in Japan

and abroad.

In 1992 a new tool manufacturing plant equipped with modern CAD & CAM

system was put into operation.

Here work groups of most experienced tool designers and skilled workers.

Their long experience, accumulated know hows and unique ideas are embodied

in the products.

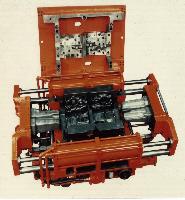

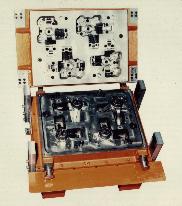

NANIWA can accept orders not only for tooling, but also a complete

set of machine with tooling - this is a big assurance for Customers.

Test blow of cores is possible on multipurpose core blowing machine in

this plant.

Originally designed parts for tooling ( slit vents, blow nozzles, seal

rubber for cold box, heater couplings for quick change of core-box ) are

also available.